Welcome to Mechanical Engineering

Welcome to the world of Mechanical Engineering. Congratulations, Yes, you have selected a right career option. Mechanical Engineering has never ending opportunities and challenges. It is not just about Machines and Mechanisms but a field which contains minds and people who think, conceptualise, design, build, and develop technology for the service of society and nation. The domain, where many ideas are conceived and developed, is delivered worldwide. Knowledge in Mechanical Engineering "empowers" us to realise any wild dream. Mechanical Engineering is a parent engineering discipline which is further connected with Robotics, Mechatronics, Automation, CFD, Artificial Intelligence, Ergonomics, Cryogenics, Aerospace, Solar/Wind energy and many more. Mechanical Engineering is not just a cause of livelihood but sea of opportunities to prove that sky can be the only limit. Mechanical Engineering is a panacea for challenging attitude and skill seeking entities. "

More Info...

Vision

To be an excellence centre in the field of imparting mechanical engineering education, training and empowering technical skills and to adapt research and transformation culture.

Mission

M1: To educate students the mechanical engineering knowledge for life-long learning and empower their professional skills to meet the career challenges

M2: To commit for professionalism, initiative, integrity, innovation and willingness to change and adopt research culture

M3: To facilitate project-based learning for research, innovation and transfer of technology to serve the society

PO-1: Apply basic knowledge of mathematics, science and engineering principles to solve technical problems, related directly to Mechanical Engineering.

PO-2: Design and analyze system components, or processes, to meet the desired needs in Mechanical Engineering.

PO-3: Design system and conduct experiments to find suitable solution in the field of Mechanical engineering.

PO-4: Identify, visualize, formulate and solve engineering problems in the field of Mechanical Engineering.

PO-5: Ability to bring technology transfer to toil the society and environment. Use techniques, skills, and modern engineering tools necessary for engineering practice with appropriate considerations for constraints.

PO-6: Ability to use adaptable research solutions to showcase impact of technology development on society, by applying scientific reasoning methodologies, appropriate and relevant skills towards the understanding of the impact of engineering solutions on the society in a global and social context.

PO-7: Impart knowledge on contemporary issues about society and environment.

PO-8: Apply ethical principles and responsibilities during professional practice.

PO-9: Function effectively as team member/leader in a multi-disciplinary team and create user friendly environment.

PO-10: Communicate effectively in oral, written, visual and graphical modes within team, and group environments.

PO-11: Apply different techniques, skills and modern engineering tools necessary for engineering projects.

PO-12: Recognize the need for professional advancement by engaging in lifelong learning.

Programme Specific Outcomes

PSO I: Engineering Graduates will be able to apply the acquired mechanical engineering knowledge for the benefit and improvement of self and the society.

PSO II: Engineering Graduates will be able to implement the learnt principles and skills to analyze, evaluate and create more advanced mechanical systems or processes.

Programme Educational Objectives

PEO1: To acquire basic principles and knowledge of science and mathematics and its application through engineering skills

PEO2: To achieve peer recognition as an individual and able to lead a team through engineering skill demonstration.

PEO3: To develop abilities for successful professional career with ethical and moral values.

PEO4: A competency to pursue life-long learning and to deal with challenges.

Prof. Dr. Mohammed Wasim Khan

HOD, Mechanical Department

"Hi, Seasons of Greetings to all,

It gives me an immense pleasure to introduce you the Department of Mechanical Engineering of Theem College of Engineering which has fully developed 17 labs, workshop with carpentry, welding, sheet metal sections. Machine shop withall shopfloor machinaries. In addition to that we have CNC lathe and CNC milling lab, CAD/CAM lab with high configuration PCs operated/controlled through independent server with 50 Mbps internet connectivity and ICT enabled class rooms. The department is little less than a decade old but it has both industry and teaching experience faculty team with average experience of 8 years and all are expert in carving and inculcation engineering skills and entrepreneur able engineering technology. Department of Mechanical Engineering nurtures the ideas born in the minds of our students through its state of art workshop ""Theem Makers Vector"" which has an independent space with all machines and tools to support the fully loaded workshop. Finishing School Scheme, a mission and a special effort of H. J. Thim Trust, is well planned to fortify the employability and readiness to accept the job challenges. It is the quill/feather in the crown of Mechanical Engineering Department. We empower our engineers ready with industry skill and confidence by providing training in collaboration with industry experts and our faculty. Research & Development (R&D) and Intellectual Property Rights Cell (IPRC) supervise all the state of art labs which are established to cater the objectives of ""Finishing School Scheme"". In the field of Quality Assurance and Quality Control, our students are trained by ""Industry Ready Quality Training Lab"". ""Entrepreneurship and Start-up Lab"" provides a complete entrepreneurial and start-up assistance to the budding entrepreneurs. In the field of maintenance schedules, practices and use modern tools and techniques, our engineers are trained by ""Industry Ready Maintenance Training Lab"". Our students gain vast experiences participating continuously in the various National and Prestigious Competitions - SUPRA, Go-Cart, Al Baja, Robot Wars and Races through SAE Collegiate Club."

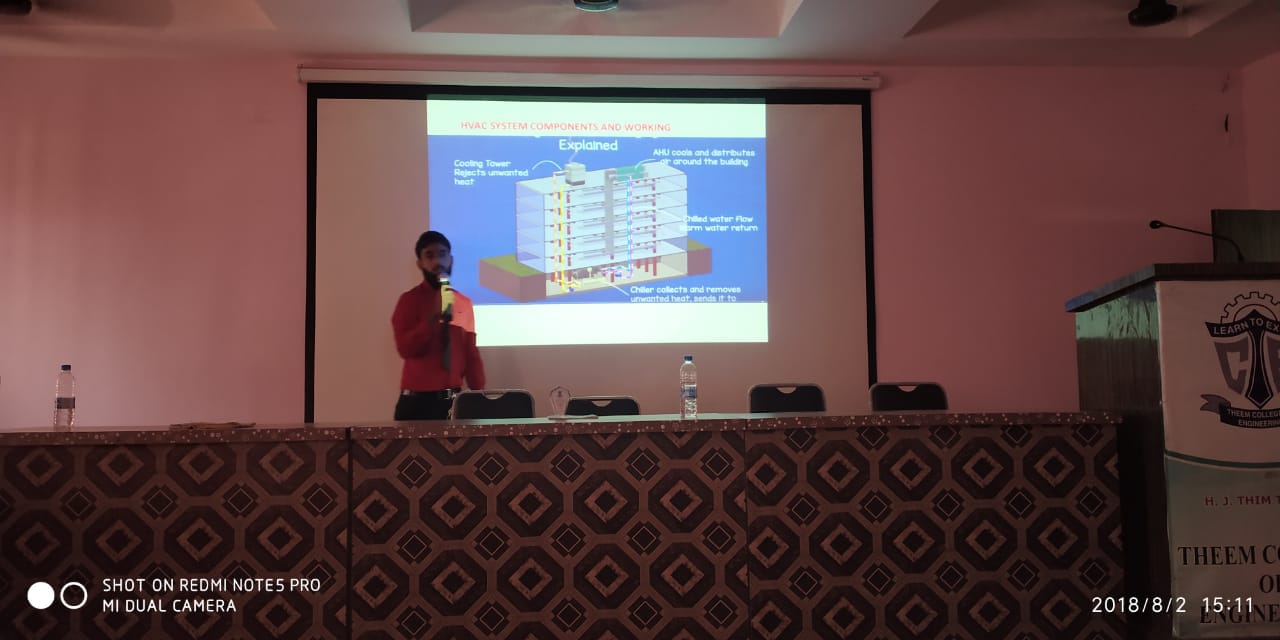

Event Description Photos

| Industrial Visit to GTPS, Uran | Industrial Visit to Gas Turbine Power Station, Uran on 2nd November 2018. |  More Photos |

| Seminar on MEP | Seminar on Mechanical-Electrical & Plumbing Utility Systems |  More Photos |

Teaching Staff

| Designation: | Asst Professor |

| Qualification: | ME, BE |

| Area of Interest: | Cad/cam,fea,material Science,manufaturing Process, Renewable Energy. |

| Email: | wasim.khan@theemcoe.org |

| Designation: | Asst Professor |

| Qualification: | PhD, BE |

| Area of Interest: | |

| Email: |

| Designation: | Asst Professor |

| Qualification: | ME THERMAL, BE MECHANICAL |

| Area of Interest: | Mechanical Vibration,operation Research,strength Of Materials,heat Transfer,theory Of Machines-ii, Dynamics Of Machines,tfpe,fluid Mechanices,thermodynamies,kinematies Of Machines,refrigeration And Ac |

| Email: | iqbal.mansuri@theemcoe.org |

| Designation: | Assistant Prof |

| Qualification: | ME, BE |

| Area of Interest: | |

| Email: |

| Designation: | Assistant Prof |

| Qualification: | ME, BE |

| Area of Interest: | |

| Email: |

| Designation: | Assistant Prof |

| Qualification: | M Tech, BE |

| Area of Interest: | Thermal Engineering, Engineering Mechanics Engineering Graphics, Materials And Metallurgy, Fm |

| Email: | zahir.khan@theemcoe.org |

| Designation: | Assistant Prof. |

| Qualification: | ME, BE |

| Area of Interest: | |

| Email: | ramiz.papanji@theemcoe.org |

| Designation: | Assistant Prof. |

| Qualification: | ME, BE |

| Area of Interest: | |

| Email: |

| Designation: | Assistant Prof |

| Qualification: | ME, BE |

| Area of Interest: | |

| Email: |

| Designation: | Assistant Prof. |

| Qualification: | ME, BE |

| Area of Interest: | |

| Email: |

Non-Teaching Staff

| Designation: | Fitter |

| Qualification: |

| Designation: | Lab. Assistant |

| Qualification: |

| Designation: | Workshop Instructor |

| Qualification: | XII & ITI (Fitter) |

| Designation: | Lab Assistant |

| Qualification: | Diploma |

| Designation: | lab Assistant |

| Qualification: |

| Designation: | Lab. Assistant |

| Qualification: |

Name of the Laboratory Description

| Fm And Hmc Lab

View Lab | We have Bernoullis apparatus, calibration of Venturimeter & Orifice meter, losses in pipe friction apparatus, Reynolds apparatus, Pitot Tube, Wind Mill |

| Rac

View Lab | Comfort and luxuries of human life is possible only due to refrigeration and air conditioning, which makes it possible to create artificial environment as per application. This laboratory has equipped with all the facility for students to cater the knowledge of energy efficient cooling, heating and ventilation by using water cooler, heat pump, window air conditioner and vapor absorption refrigeration test setups. Ice plant test setup is unique feature of lab to teach the energy efficient ice making technique. |

| Som And Mt Lab

View Lab | The strengths lab is equipped with testing systems for learning principles of strength of materials, observing mechanical behaviors of common engineering materials under various loading conditions. |

| Thermal

View Lab | In Thermal Engineering lab, student should able to learn construction and working of different boilers with mountings and accessories. Heat transfer laboratory includes different experimental setup for determining thermal conductivity of various materials like insulating powder, metal rod, composite slab and natural and forced convection models. Experimental setup for radiation measurement to determine Stefan Boltzmann?s constant. Parallel and counter flow Heat Exchangers. In Heat transfer lab, student will learn to find thermal conductivity of various materials, effectiveness of heat exchangers, heat transfer coefficient and fin effectiveness.. |

| Machine Shop

View Lab |

| I. C. Engine Lab

View Lab | This laboratory focuses on learning different CONCEPTS OF Internal Combustion Engine and its practical aspects, Such as Trial on Petrol / Diesel Engines as well as Performance for MORSE test. |

| Workshop

View Lab | The work shop is having all the modern facilities as per the norms of All India Council for Technical Education (AICTE). Facility available for training in Machine Shop, Turning Shop, Welding Shop, Fitting Shop, Carpentry & Pattern making, Plumbing & Sheet metal, Smithy shop. |

| Cnc Machine

View Lab |

| Cad/cam Lab2

View Lab | The department has Computer Aided Design (CAD) laboratory, dedicated 24 computers are available with desired configuration. All computers are interconnected with LAN and internet facility. The CAD lab computers are installed with AutoCAD, Solidworks, ANSYS software. The lab is available to UG students for practical and project work. LCD projector is available to the students for project and seminar presentations. |

| Mechatronics

View Lab | Mechatronics is an electromechanical systems that merges mechanical, electrical, control system, and embedded software design. The department has a well-equipped Laboratory with the all equipments and infrastructure. The laboratory is equipped PLC trainer kit, 8085 Microprocessor Trainer kit, Pneumatic Trainer kit, Hydraulic Trainer kit, DC position servo mechanism, AC position seervo mechanism. Material Technology- To understand this subject students have fundamental knowledge of engineering chemistry and physics. The objective of the course is to understand the basic principles of material science and technology. It includes mechanical testing to determine mechanical properties. It also includes various heat treatment, introduction of furnaces and various engineering materials and their applications. |

| Cad/cam Lab1

View Lab | The department has Computer Aided Design (CAD) laboratory, dedicated 24 computers are available with desired configuration. All computers are interconnected with LAN and internet facility. The CAD lab computers are installed with AutoCAD, Solidworks, ANSYS software. The lab is available to UG students for practical and project work. LCD projector is available to the students for project and seminar presentations. |

| Md Lab

View Lab |

| Mmm Lab

View Lab | This course introduces undergraduate students to Metrology and Quality Control. The background includes a sound knowledge of measurements. The course aims at to familiarize, to understand the principles of metrology of screw threads, gear measurement, study of measuring machines, recent trends in engineering metrology. To learn use of standard practices and standard data, learn to use statistical concept, control chart for variables, control chart for attributes, acceptance sampling. |

| Tom And Vibration Lab

View Lab | In view of the requirements of mechanical engineering sector, this lab includes different major test rings equipped with motorized gyroscope, universal governor, balancing apparatus, epicyclic gear train & holding torque, two rotor damping system, different working models with gear boxes etc. and charts. Students are able to learn about different machines, mechanism and working principle. Also they are able to design and analyze the machine components with importance of well balancing, minimizing vibrations etc. |

| Engineering Mechanics

View Lab | Engineering Mechanics lab |

| Cad-cam

View Lab | The lab is designed for conducting practical,s based on Data Base Management system. The main objective of lab is to provide practical environment to encourage the students for developing practical skills |

| Drawing Hall

View Lab | In engineering it is said that engineering drawing is the language of communication for worldwide engineers. In order to obtain this knowledge student must be familiar with engineering drawing that is to read the drawing and also make a neat sketch of objects in standard format. The lab consists of more than 25 drawing tables for drawing of sheets. |

Notice Board

| Sem 3 | Applied Mathematics III | Demonstrate the ability of using Laplace Transform in solving the Ordinary Differential Equations and Partial Differential Equations | Demonstrate the ability of using Fourier Series in solving the Ordinary Differential Equations and Partial Differential Equations | Solve initial and boundary value problems involving ordinary differential equations | Identify the analytic function, harmonic function, orthogonal trajectories | Apply bilinear transformations and conformal mappings | Identify the applicability of theorems and evaluate the contour integrals. | Thermodynamics | Demonstrate application of the laws of thermodynamics to wide range of systems. | Write steady flow energy equation for various flow and non-flow thermodynamic systems | Compute heat and work interactions in thermodynamics systems | Demonstrate the interrelations between thermodynamic functions to solve practical problems. | Use steam table and mollier chart to compute thermodynamics interactions | Compute efficiencies of heat engines, power cycles etc. | Strength of Materials | Demonstrate fundamental knowledge about various types of loading and stresses induced. | Draw the SFD and BMD for different types of loads and support conditions | Analyse the stresses induced in basic mechanical components. | Estimate the strain energy in mechanical elements. | Analyse the deflection in beams. | Analyse buckling and bending phenomenon in columns, struts and beams. | Production Process | Demonstrate understanding of casting process | Illustrate principles of forming processes | Demonstrate applications of various types of welding processes. | Differentiate chip forming processes such as turning, milling, drilling, etc. | Illustrate the concept of producing polymer components and ceramic components. | Distinguish between the conventional and modern machine tools. | Material Technology | Identify various crystal imperfections, deformation mechanisms, and strengthening mechanisms | Demonstrate understanding of various failure mechanisms of materials. | Interpret Iron-Iron carbide phase diagram, and different phases in microstructures of materials at different conditions. | Select appropriate heat treatment process for specific applications. | Identify effect of alloying elements on properties of steels | Illustrate basics of composite materials, Nano- materials and smart materials. |

| Sem 4 | Applied Mathematics IV | Solve the system of linear equations using matrix algebra with its specific rules | Demonstrate basics of vector calculus | Apply the concept of probability distribution and sampling theory to engineering problems | Apply principles of vector calculus to the analysis of engineering problems | Identify, formulate and solve engineering problems | Illustrate basic theory of correlations and regression | Fluid Mechanics | Define properties of fluids and classification of fluids | Evaluate hydrostatic forces on various surfaces and predict stability of floating bodies | Formulate and solve equations of the control volume for fluid flow systems | Apply Bernoulli?s equation to various flow measuring devices | Calculate resistance to flow of incompressible fluids through closed conduits and over surfaces | Apply fundamentals of compressible fluid flows to relevant systems | Industrial Electronics | Illustrate construction, working principles and applications of power electronic switches | Identify rectifiers and inverters for dc and ac motor speed control | Develop circuits using OPAMP and timer IC555 | Identify digital circuits for industrial applications | Illustrate the knowledge of basic functioning of microcontroller | Analyse speed-torque characteristics of electrical machines for speed control | Production Process II | Demonstrate understanding of metal cutting principles and mechanism | Identify cutting tool geometry of single point and multipoint cutting tool | Demonstrate various concepts of sheet metal forming operations | Demonstrate concepts and use of jigs and fixtures | Illustrate various non-traditional machining techniques | Illustrate concepts and applications of additive manufacturing | Kinematics of Machinery | Define various components of mechanisms | Develop mechanisms to provide specific motion | Draw velocity and acceleration diagrams of various mechanisms | Draw Cam profile for the specific follower motion | Analyse forces in various gears | Select appropriate power transmission for specific application |

| Sem 5 | Internal Combustion Engines | Demonstrate the working of different systems and processes of S.I. engines | Demonstrate the working of different systems and processes of C.I. engines | Illustrate the working of lubrication, cooling and supercharging systems. | Analyse engine performance | Illustrate emission norms and emission control | Comprehend the different technological advances in engines and alternate fuels | Mechanical Measurement and Control | Classify various types of static characteristics and types of errors occurring in the system. | Classify and select proper measuring instrument for linear and angular displacement | Classify and select proper measuring instrument for pressure and temperature measurement | Design mathematical model of system/process for standard input responses | Analyse error and differentiate various types of control systems and time domain specifications | Analyse the problems associated with stability | Heat Transfer | Identify the three modes of heat transfer (conduction, convection and radiation). | Illustrate basic modes of heat transfer | Develop mathematical model for each mode of heat transfer | Develop mathematical model for transient heat transfer | Demonstrate and explain mechanism of boiling and condensation | Analyse different heat exchangers and quantify their performance | Dynamics of Machinery | Demonstrate working Principles of different types of governors and Gyroscopic effects on the mechanical systems | Illustrate basic of static and dynamic forces | Determine natural frequency of element/system | Determine vibration response of mechanical elements / systems | Design vibration isolation system for a specific application | Demonstrate basic concepts of balancing of forces and couples | Machining Sciences And Tool Design | Calculate the values of various forces involved in the machining operations | Design various single and multipoint cutting tools | Analyse heat generation in machining operation and coolant operations | Illustrate the properties of various cutting tool materials and hence select an appropriate tool material for particular machining application | Demonstrate the inter-relationship between cutting parameters and machining performance measures like power requirement, cutting time, tool life and surface finish | Demonstrate basic concepts of balancing of forces and couples |

| Sem 6 | Metrology and Quality Engineering | Demonstrate inspection methods and different gauges | Illustrate working principle of measuring instruments and calibration methodology | Illustrate basic concepts and statistical methods in quality control | Demonstrate characteristics of screw threads, gear profile, and tool profile | Illustrate the different sampling techniques in quality control | Illustrate different nondestructive techniques used for quality evaluation | Machine Design ? I | Demonstrate understanding of various design considerations | Illustrate basic principles of machine design | Design machine elements for static as well as dynamic loading | Design machine elements on the basis of strength/ rigidity concepts | Use design data books in designing various components | Acquire skill in preparing production drawings pertaining to various designs | Finite Element Analysis | Solve differential equations using weighted residual methods | Develop the finite element equations to model engineering problems governed by second order differential equations | Apply the basic finite element formulation techniques to solve engineering problems by using one dimensional elements | Apply the basic finite element formulation techniques to solve engineering problems by using two dimensional elements | Apply the basic finite element formulation techniques to find natural frequency of single degree of vibration system | Use commercial FEA software, to solve problems related to mechanical engineering | Refrigeration and Air Conditioning | Demonstrate fundamental principles of refrigeration and air conditioning | Identify and locate various important components of the refrigeration and air conditioning system | Illustrate various refrigeration and air conditioning processes using psychometric chart | Design Air Conditioning system using cooling load calculations. | Estimate air conditioning system parameters | Demonstrate understanding of duct design concepts | Mechatronics | Identify the suitable sensor and actuator for a mechatronics system | Select suitable logic controls | Analyse continuous control logics for standard input conditions | Develop ladder logic programming | Design hydraulic/pneumatic circuits | Design a mechatronic system |

| Sem 7 | Machine Design- II | Select appropriate gears for power transmission on the basis of given load and speed. | Design gears based on the given conditions. | Select bearings for a given applications from the manufacturers catalogue. | Select and/or design belts for given applications. | Design cam and follower and clutches | CAD/CAM/CAE | Identify proper computer graphics techniques for geometric modelling. | Transform, manipulate objects and store and manage data. | Prepare part programming applicable to CNC machines. | Use rapid prototyping and tooling concepts in any real life applications. | Identify the tools for Analysis of a complex engineering component. | Mechanical Utility Systems | Describe operating principles of compressors and pumps | Evaluate performance of reciprocating/rotary compressors | Evaluate performance of reciprocating/rotary compressors | Interpret possibilities of energy conservation in pumping and compressed air systems | Production Planning and Control | To provide a comprehensive exposure to Production Planning & Control (PPC) and its significance in Industries. | To acquaint students with various activities of PPC. | To give insight into the ongoing & futuristic trends in the control of inventory. | To appraise about need and benefits of planning functions related to products and processes. | To give exposure to production scheduling and sequencing | Power Plant Engineering | Comprehend various equipments/systems utilized in power plants | Discuss types of reactors, waste disposal issues in nuclear power plants | Illustrate power plant economics | Operations Research | Illustrate the need to optimally utilize the resources in various types of industries. | Apply and analyze mathematical optimization functions to various applications. | Demonstrate cost effective strategies in various applications in industry. |

| Sem 8 | Design of Mechanical Systems | Design material handling systems such as hoisting mechanism of EOT Crane, belt conveyors. | Design engine components such as cylinder, piston, connecting rod and crankshaft from system design point of view. | Design pumps for the given applications. | Prepare layout of machine tool gear box and select number of teeth on each gear. | Industrial Engineering and Management | Illustrate the need for optimization of resources and its significance in manufacturing industries, in order to enhance overall productivity. | Develop capability in integrating knowledge of design along with other aspects of value addition in the conceptualization and manufacturing stage of various products. | Demonstrate the concept of value analysis and its relevance. | Manage and implement different concepts involved in methods study and understanding of work content in different situations. | Describe different aspects of work system design and facilities design pertinent to manufacturing industries. | Identify various cost accounting and financial management practices widely applied in industries. | Refrigeration and Air Conditioning | Discuss fundamental refrigeration and air conditioning principles | Identify and locate various important components of the refrigeration and air conditioning system | Illustrate various refrigeration and air conditioning processes using psychometric chart | Design and analyze complete air conditioning system | Renewable Energy Sources | Demonstrate need of different renewable energy sources and their importance | Calculate and analyse utilization of solar and wind energy | Illustrate design of biogas plant | Estimate alternate energy sources India | Automobile Engineering | Demonstrate & explain various systems in an automobile | Describe importance and features of different systems like axle, differential, brakes, steering, suspension, wheel and balancing etc. | Explain principle of operation, construction and applications of various sensors used in modern automobile. |